Anodizing aluminum service

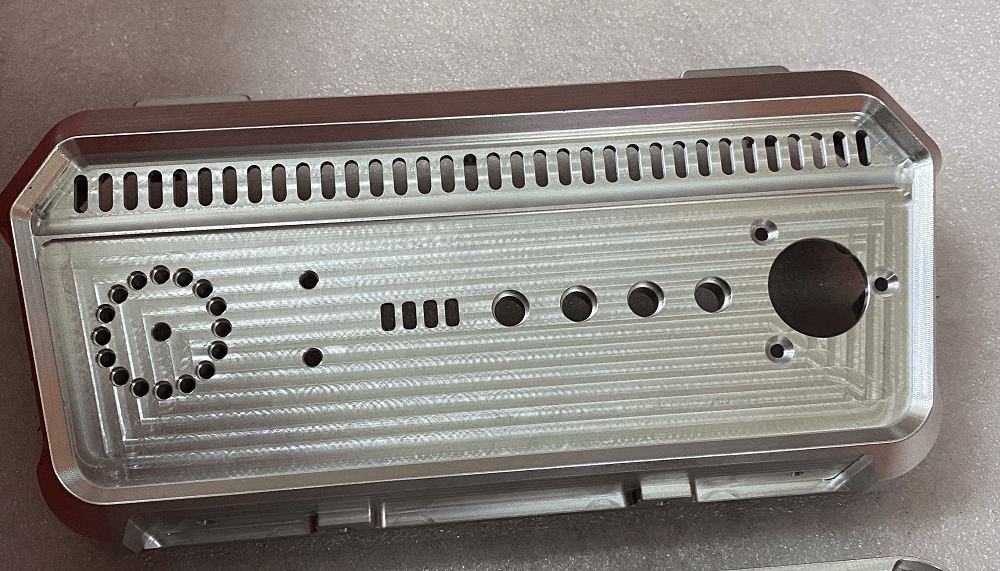

Anodizing service is usually the first surface treatment option for aluminum parts.

So, take the oxidation treatment for the aluminum machining parts after machining work. There are several types of anodizing and they have their own benefits.

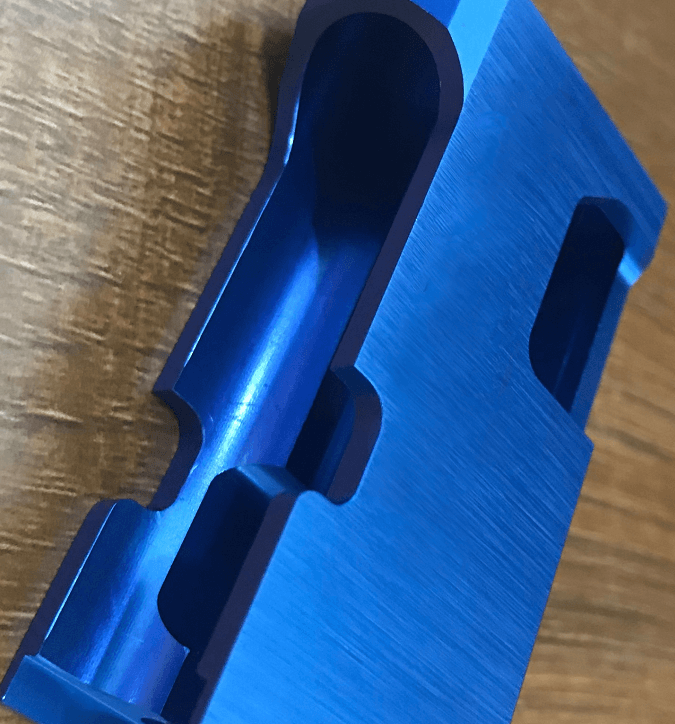

Aluminum anodizing colors are rich. You can choose one of the general colors. Or customize your own color.

How the process work?

First, immerse the aluminum in an acidic electrolyte. The metal acts as the anode, while a cathode is also present in the solution. Then, direct current pass through the electrolyte and forms an oxide film on the surface of the aluminum parts.What are the benefits?

The aluminum oxidation treatment changes the surface state and performance of the parts. Such as surface coloring, improving corrosion resistance, enhancing wear resistance and hardness., etc.Thickness of oxide film

The thickness can be controlled by adjusting the parameters of the process. Such as the duration of the process or the voltage applied.Colors options

The coating layer is usually transparent and left as it is. But aluminum parts can also be anodized in many colors. So the parts can get aesthetic appearance.

Why aluminum need anodizing?

Though, the aluminum is a kind of highly corrosion-resistant material. But the surface oxidizes and loses its corrosion and bran resistance slowly over time. In addition, aluminum is also very sensitive to acids. Therefore, the surface component layer is destroyed when confronted with acidity.What are the benefits of anodized treatment ?

The oxidation film on the surface enhances the performance, aesthetics, and longevity of aluminum parts. What’s more, it makes aluminum parts more versatile and reliable to suit various industries and applications.Improve Corrosion Resistance

As the film obtained by anodic oxidation has been properly closed, so it has good stability in the atmosphere.

Besides, its corrosion resistance is good when in the acid solutions like sulfuric acid solution, oxalic acid solution, or chromic acid solution.

Moreover, Hard coat oxide film resists corrosion for thousands of hours in ω=0.03NaCl salt spray.

Increase surface hardness

How it increases the surface hardness?

After the oxidation treatment of aluminum, especially hard oxidation treatment, a protective film is obtained on the surface to improve its hardness.

Thickness of the coating

The thickness of the oxide film can reach 5~20 microns, and the hard oxide film can reach 60~200 microns. Moreover, the hardness of hard oxidized aluminum parts can reach about HV500.

Improved heat resistance

The anodizing process creates a protective oxide layer on its surface. The layer works as a barrier, preventing direct contact between the aluminum and extreme heat sources.

It helps to enhance the material’s resistance to heat damage. For example, The melting point of the hard oxide film is up to 2320 k

Improve wear resistance

1. Surface hardness improves.

The hard and dense oxide layer on the surface significantly improves the surface hardness of the parts. So it makes it more resistant to wear and tear.

2. Layer is thick and tight.

It forms a thick and tight layer on the surface. Even though the coatings wear out over time. But the underlying metal maintains the integrity.

3. Sel-lubricating properties.

The coating layer has self-lubricating properties. They help reduce friction between the surface of aluminum and other materials. It extends the life of the material in applications.

These factors together contribute to improving the wear resistance of anodized aluminum.

Aesthetic appeal

There are many colors for your options. Or you can customize the color and pattern.

More options are available.

– multiple anodizing coloring

– fireworks patterns

– wood patterns

– oxidation offset transfer printing

– porcelain oxidation., etc.

Anodized finish can meet your need for branding purposes or match the overall design aesthetics or products.

Below are the common types of Aluminum surface oxidation processes. Each one offers its unique properties and characteristics. Which to choose depends on the desired properties and requirements of the end product.

Sulfuric Acid Anodizing (SAA):

SAA is the most common and widely used anodized process for aluminum parts.

What is SAA process?

Immerse the parts in a dilute sulfuric acid electrolyte and applies a direct current to get the layer.

Colors of SAA

SAA produces not only a transparent oxide layer (clear anodizing) but also can be dyed in different colors.

Hard Anodizing (Type III Anodizing):

What is hard coat anodizing?

Type III processes by reducing the anodizing temperature or sulfuric acid concentration.

An enhanced form of SAA

It creates a thicker and harder oxide layer.

Thickness of coating layer

Generally, the thickness is required to be 25-150 μm. The majority of hard coat anodizing films have a thickness of 50-80 μm.

Benefits

Excellent wear resistance, increased hardness, and improved corrosion resistance.

Chromic Acid Anodizing (CAA):

What is CAA?

CAA uses chromic acid as the electrolyte. The oxide layer is thinner and more corrosion-resistant than SAA.

Application of CAA

Where the dimensional stability of the parts is critical. Such as aerospace.

Disadvantages of CAA

Chromic acid poses environmental and health concerns due to its toxicity.

Alternative anodizing processes for CAA

Alternative anodized processes are regularly preferred. Such as SAA or organic acid anodized. Because they are safer and more environmentally friendly in nature.

Tartaric-Sulfuric Acid Anodizing (TSA):

What is TSA?

TSA is also known as the Adams process. It uses a mixture of sulfuric acid and tartaric acid in the electrolyte. The tartaric acid helps improve the distribution and quality of the anodizing coating.

Benefits of TSA

Prevent excessive attack on the copper constituents.

Application of TSA

Primarily used for aluminum alloys with high copper content. TSA is widely used in industries where corrosion resistance and aesthetic properties are crucial.

Boric Sulfuric Acid Anodizing (BSAA):

What is BSAA?

BSAA is similar with SAA. The difference is BSAA has the addition of a small amount of boric acid in the electrolyte.

Benefits of BSAA

Oxide layer is thinner and smoother. It improves adhesion for subsequent coatings or adhesives.

There are wide options of aluminum anodized colors for machining parts. Below are the colors that generally used.

Besides, you can customize the colors and appearance of your parts.

our services

Additional options of finishes for aluminum machining parts are as below. The most common ones are brushing, and sandblasting. Besides, you can customize patterns.

Brush anodizing

Brush anodizing refers to processing straight-line patterns on the surface of aluminum.

Patterns:

straight lines, cross lines, random lines, threads, corrugations, and spiral lines. You can choose the one you like.

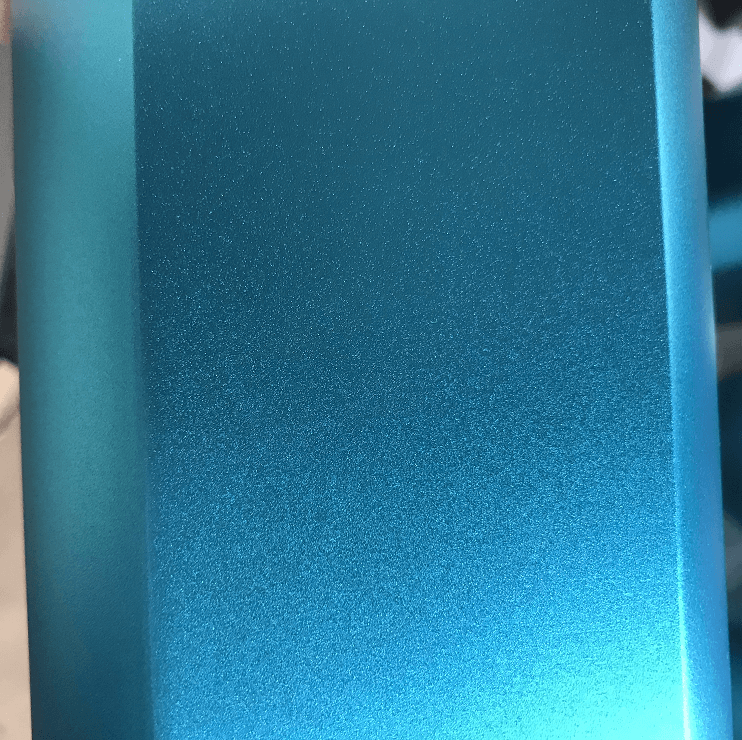

sandblasted anodized finish

Sandblasting is to use external forces to spray sand to the surface of the workpiece.

Purpose:

To achieve coarsening, cleaning, decoration, and other effects for parts.

Design tips for turning machining

Design tips for turning machining parts When you receive the quotation of turning parts from manufactures, you may find that the prices are out of your expectation and budget limit. Then you may need to find ways to reduce the cost. Here we share some design tips for your to get lower prices.By optimizing the

what is a 5 axis cnc machine

CNC technology has been getting more advanced in recent years. One specific advancement is the use of five-axis linkage CNC machining centers, which have become increasingly popular in various industries. These 5 axis CNC machines are highly efficient and produce high-quality results. They are particularly beneficial when manufacturing complex-shaped parts. Double-column Machining Center(5-Face Machining)-MCR-A5CⅡ) ■

laser etching aluminum

Laser etching aluminum Fiwok provides laser etching aluminum services to satisfy your need for branding and identification. With advanced laser marking machines, we are capable of black and white etchings for aluminum parts. ■ What is laser etching ? ■ Advantages of laser marking ■ Laser etching anodized aluminum machining parts ■ Black and white