Laser etching aluminum

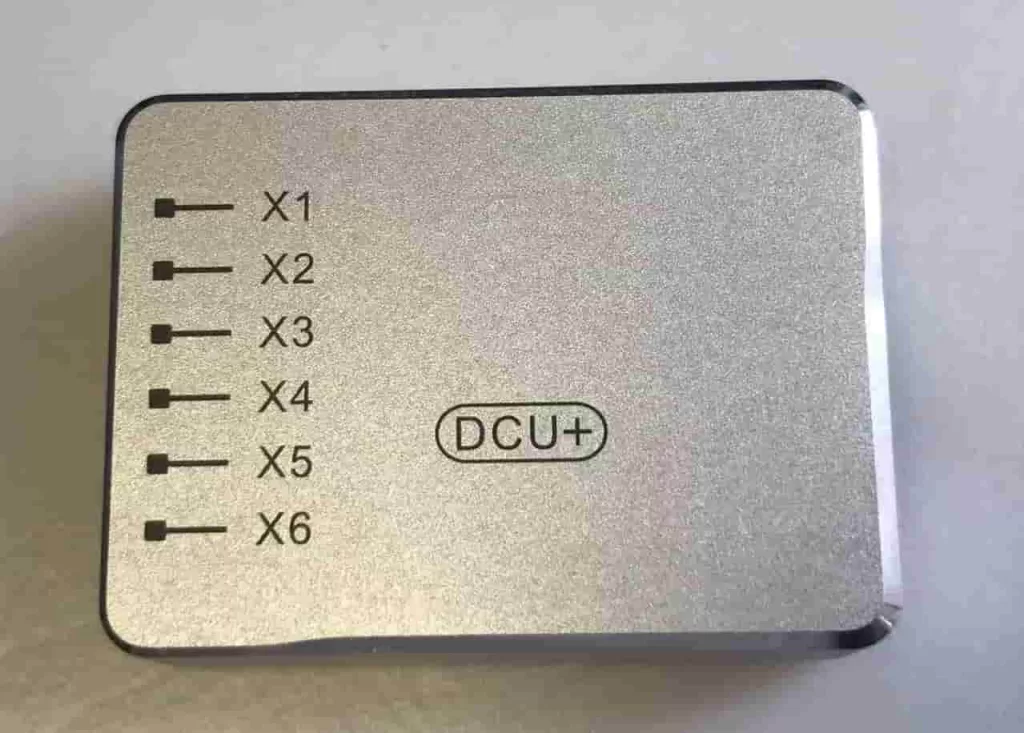

Fiwok provides laser etching aluminum services to satisfy your need for branding and identification. With advanced laser marking machines, we are capable of black and white etchings for aluminum parts.

The theories of laser etching

Advantages as below:

- Text or patterns can be marked on the surface of products with any shape.

- The workpiece will not be deformed and avoid producing internal stress.

- Laser etching is suitable for metal, plastic, glass, ceramics, wood, leather, and other materials.

- The marks are wear-resistant

- Easy to realize the automation of the production process.

- The cost of laser marking is minimal. For machined parts, the cost of this component is almost negligible compared to the machining cost.

Laser marking can mark almost all parts.

Such as pistons, piston rings, valves, valve seats, hardware tools, sanitary ware, electronic components., etc.

What is “anodized aluminum”?

Anodized aluminum refers to aluminum parts take the anodizing process to get a dense layer of oxidation. The layer can prevent oxidation of the aluminum or aluminum alloy. Clear anodized and black anodized are the very common anodizing colors that used in industries.

Laser etching is usually the first choice for marks on aluminum parts.

Nowadays, many products have logo marks or texts on the appearance. On the one hand, is to show brand image. On the other hand, it plays a role in anti-counterfeiting. For anodized aluminum, people often use laser etching to get the marks.

Laser etching clear anodized aluminum

Laser etching black anodized aluminum

Black and white etchings are the common etching colors for anodizing aluminum parts. We get the black and white etching marks on machined aluminum parts by different laser etching machine and different requirements of anodizing.

In the market, high-end cell phone logo and adaptive information usually apply black etching.

Is black etching aluminum anodized parts easy?

The answer is not. The Common laser marking machines on the market are 20 watt fiber laser etching machine. It can not play black mark on anodized aluminum.

Black laser etching

How can etch black on anodized aluminum parts?

There are 2 necessary conditions to meet.

1st, the laser etching machine must support the black etching.

These machines are much higher than the general finer laser etching machines. Our laser engraving can do it. It has characteristics of fine spots, uniformity, stability. Besides, it can also process all kinds of metal or plastic materials.

2nd, it must be anodized aluminum.

It has high requirements on the anodizing process. Most of the anodized aluminum parts can’t laser etch in black. So, the manufacturer must have rich anodized experience on it.

Our company has batch processed and produced a lot of aluminum parts in black etching. We always satisfied our clients with good quality. Seeing, we have rich experience in machining services and anodizing and black etching. Just provide us the drawings, we won’t let you down.

White etching

The aluminum etching marks are generated by the laser focus to vaporize the surface of the material. Generally hit out the material’s own color.

So, white etching is the general marking way for anodized aluminum on the market. When printing white, you need to adjust the parameters of laser marking. White etching should be fast and low power.

Fiwok provided white etching for your CNC machining aluminum parts after anodized. We can control well the size and location of the logos and texts. Start by consulting our custom parts machining services now!

The video shows you how a laser etching machine mark on round anodized aluminum machining parts.

The cost of laser etching usually are not expensive. For the machining parts, the laser etching cost can be nearly omitted.

The etching price for each part is typically $0.07USD to 0.7USD, depending on the qty and requirements. Off course, sometimes the prices will be lower or more in some conditions.

Factors that affect the cost of laser marking on aluminum parts

Etching quantity obviously impact the cost. Generally speaking, mass production reduces the cost of etching per part significantly.

The size and shape of the part will also affect the cost of laser marking. Larger parts may need longer marking times and more powerful lasers. So they cost more.

The texts or patterns to laser marking are on the positions of different heights. When the height gap is too big, it is hard to etch all at one time. Thus, the etching works must be divided into several times to complete. It obviously increases the process time and machine-adjusting time.

It is known through the previous introduction that white etching is easy for anodized aluminum. It is not strict for the laser etching equipment and anodizing. Yet, black etching is harder. The machine for it is much more expensive. And the requirements for aluminum anodizing are stricter. So black etching is more expensive than white etching.

Design tips for turning machining

Design tips for turning machining parts When you receive the quotation of turning parts from manufactures, you may find that the prices are out of your expectation and budget limit. Then you may need to find ways to reduce the cost. Here we share some design tips for your to get lower prices.By optimizing the

what is a 5 axis cnc machine

CNC technology has been getting more advanced in recent years. One specific advancement is the use of five-axis linkage CNC machining centers, which have become increasingly popular in various industries. These 5 axis CNC machines are highly efficient and produce high-quality results. They are particularly beneficial when manufacturing complex-shaped parts. Double-column Machining Center(5-Face Machining)-MCR-A5CⅡ) ■

laser etching aluminum

Laser etching aluminum Fiwok provides laser etching aluminum services to satisfy your need for branding and identification. With advanced laser marking machines, we are capable of black and white etchings for aluminum parts. ■ What is laser etching ? ■ Advantages of laser marking ■ Laser etching anodized aluminum machining parts ■ Black and white