CNC machining guide

Welcome to our comprehensive CNC machining guide! In this guide, we will explore the world of CNC machining and delve into its different types, how they work, and the advantages they offer.

CNC machining has revolutionized the manufacturing industry, enabling precise and efficient production of a wide range of products.

Whether you are a beginner or an industry professional, this guide is designed to provide you with a solid understanding of CNC machining and its various applications. Let’s dive in and discover the fascinating world of CNC machining together!

CNC (Computer Numerical Control) machining is a way to process parts with CNC automatic equipment. The workpiece processing instructions which by programming are input to the CNC machine to remove material to obtain precise and accurate size components.

The main point of machining is to enable parts to obtain higher precision and higher surface quality.

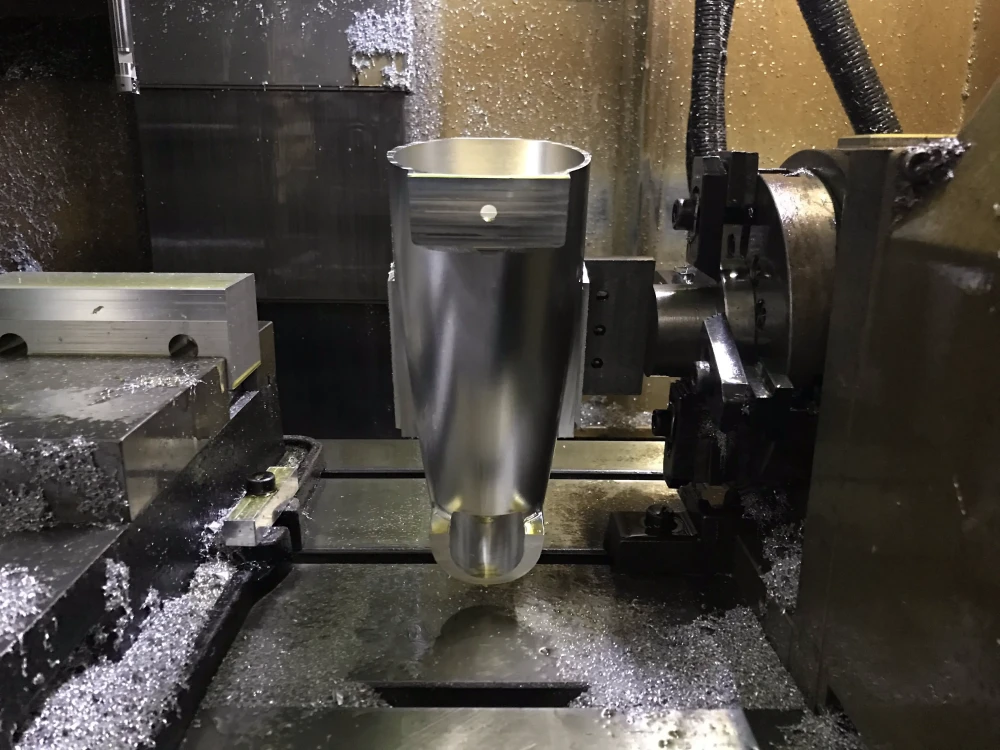

In actual production, we will simply classify CNC machines into CNC milling machines and CNC lathes.

Here are CNC machining design guides for your reference.

When the milling machine is working, the workpiece is mounted on the worktable or the indexing head. The milling cutter rotates as the main motion, supplemented by the feed motion of the worktable or the milling head.

It can process planes (horizontal planes, vertical planes), grooves (key slots, T-slots, dovetail grooves, etc.), gear parts (gears, spline shafts, sprockets), spiral surfaces (threads, spiral grooves) and various Surface. In addition, it can also be used to process the surface of the revolving body, the inner hole and the cutting work, etc.

The CNC milling machine is an automated machine controlled by the CNC system to automatically complete multiple processes in one clamping.

Compared with ordinary milling machines, CNC milling machines can process parts that ordinary milling machines cannot process. And it has higher machining accuracy, more stable quality and better efficiency.

What is 3-axis CNC machining?

In 3-axis CNC machining, the workpiece remains stationary while the cutting tool moves along the three axes to mill the part.

The four axis CNC has one more axis of rotation than the three axis CNC machine. So there are linear coordinates X axis, Y axis and Z axis, and rotation coordinates A axis B axis.

Axis A: What rotates around X axis is axis A.

B axis: What rotates around the Y axis is the axis B.

XYZ+A: Suitable for machining rotating workpiece and turning and milling combined machining

XYZ+B: The worktable is relatively small, the spindle rigidity is poor. Suitable for processing small products.

The five-axis machining centre has five axes, which are X, Y, Z, A, C. XYZ and AC form a five-axis linkage processing.

Application: is good at space surface processing, special-shaped processing, hollow processing, punching, oblique hole, bevel cutting, etc.

Advantages: Under the premise of high efficiency, the five-axis machining centre can realize the machining accuracy and quality of free-form surfaces. For example, when a three-axis machine tool is used to process complex curved surfaces, a ball-end milling cutter must be used.

Its cutting efficiency is low and the angle of the cutter cannot be adjusted freely. So it is difficult to guarantee the smoothness of the processed surface quality.

However, as the angle of the tool can be adjusted freely, the above situation can be avoided, to obtain higher cutting efficiency and high-quality surface quality.

According to the layout of the spindle, the CNC milling machines can classify into Vertical CNC milling machines & Horizontal CNC milling machines & CNC planer type milling machines.

Vertical CNC milling machines

Vertical CNC milling machine spindle and the workbench is vertical, the workbench does not do up and down movement but the spindle box do.

Its advantage is that the workpiece is easy to clamp and observe when processing, but not good for chips to remove. This structure is mainly used for small and medium-sized CNC milling machines.

Horizontal CNC milling machines

The spindle of the CNC horizontal milling machine is parallel to the working table of the machine tool. It is not easy to observe when processing, but good for chip’s removal.

They are usually equipped with tool change device (ATC).

In addition, they can achieve four or five coordinate machining by equipping with CNC rotary table.

CNC planer

CNC planer type milling machines mainly used for large or medium size of all kinds of basic large parts, plates, flanges, shell parts and moulds and so on.

It is suitable for manufacturing industries like aviation, heavy machinery, locomotive, shipbuilding, machine tool, printing, textile and moulds.

There are two ways of lathe processing: one is to fix the turning tool and process the unformed workpiece in rotation; The other is to fix the workpiece, with high-speed rotation of the workpiece, the turning tool makes lateral and longitudinal movement for precision machining.

Operation: Manual

Process range:

— shafts, flanges, pins, ring and so on.

— Internal & external rotary surface, end face.

— Various internal and external threads.

— Drilling, reaming, tapping and knurling (With the corresponding tools and accessories).

What’s the feature of Automatic lathe machining?

Process control:Cam control

Structure:The sliding block (carriage) of the automatic lathe has no drive screw and works by the push of springs and cams.

Process performance:

Multiprocess processing of small and medium-sized workpieces; automatic loading and unloading; repeated processing of a batch of the same workpieces, suitable for mass and mass production; automatically process the same product for a long time after certain settings and adjustments.

Application:

— Machining precision parts in materials of copper, aluminium, iron, plastic., etc.

— Batches production of spare parts from industries of instruments, watches, automobiles, motorcycles, bicycles, glasses, stationery, hardware sanitary ware, electronic parts, connectors, computers, mobile phones, electromechanical, military and other industries.

Process control: Computer program

Structure:The carriage of CNC lathes is basically similar to that of ordinary lathes. The carriage is driven forward or backward by a stepping motor. The clamping tools are mostly three-jaw chucks.

Features:

Usually program the process tool path by software like CAD or CAM. It can also be manually designed parts or tool paths. Then upload the generated coded computer file to the CNC machine tool, and then the machine tool will automatically produce the required parts that have been programmed and designed.

Application:

Inner and outer cylindrical surface inner and outer conical surface of arbitrary cone Angle; inner and outer curved surface of complex rotation parts ; cylindrical and conical thread of shaft parts or flange parts; and can be used for grooving, drilling, reaming, reaming and boring.

Prototypes production, small and medium batch production.

Design tips for turning machining

Design tips for turning machining parts When you receive the quotation of turning parts from manufactures, you may find that the prices are out of your expectation and budget limit. Then you may need to find ways to reduce the cost. Here we share some design tips for your to get lower prices.By optimizing the

what is a 5 axis cnc machine

CNC technology has been getting more advanced in recent years. One specific advancement is the use of five-axis linkage CNC machining centers, which have become increasingly popular in various industries. These 5 axis CNC machines are highly efficient and produce high-quality results. They are particularly beneficial when manufacturing complex-shaped parts. Double-column Machining Center(5-Face Machining)-MCR-A5CⅡ) ■

laser etching aluminum

Laser etching aluminum Fiwok provides laser etching aluminum services to satisfy your need for branding and identification. With advanced laser marking machines, we are capable of black and white etchings for aluminum parts. ■ What is laser etching ? ■ Advantages of laser marking ■ Laser etching anodized aluminum machining parts ■ Black and white