CNC Machining materials

The CNC machining materials include metal materials and plastic materials. Tell us the material name or code for the parts, we will get them and use them in machining. Besides, customer-supplied is also available.

Table of Contents

Ferrous metal materials mainly refer to iron and its alloys. Such as steel, pig iron, ferro alloy, cast iron, etc. The generally used ferrous metal materials in CNC machining are structural alloy steel, carbon structural steel, stainless steel, tool steel, free-cutting steel, and so on.

steel materials for CNC machining

| Name | Description | ISO | JIS | DIN | ASTM | BS | GB |

|---|---|---|---|---|---|---|---|

| carbon structural steel | good plasticity and toughness, easy to forming and welding | E235 | SS400 | S235 | A570 | S235 | Q235 |

| C35E4 | S35C | C35 | 1035 | 1035 | 35 | ||

| C40E4 | S40C | C40E | 1040 | 1040 | 40 | ||

| C45E4 | S45C | C45 | 1045 | 1045 | 45 | ||

| C50E4 | S50C | C50E | 1050 | 1050 | 50 | ||

| structural alloy steel | high tensile strength and buckling strength ratio,high toughness and fatigue strength | – | – | 24CrMoV55 | – | – | 25Cr2MoVA |

| 20Cr4 | SCr420 | 20Cr4 | 5120 | 527A20 | 20Cr | ||

| 41Cr4 | SCr440 | 41Cr4 | 5140 | 530A40 | 40Cr | ||

| 34CrMo4 | SCM435 | 34CrMo4 | 4135 | 708A37 | 35CrMo | ||

| SNCM439 | – | 36CrNi-Mo4 | 4340 | 816M40 | 40CrNiMo | ||

| SCM440 | 42CrMo4 | 42CrMo4 | 4140 | 708M40 | 42CrMo | ||

| free-machining steel | Good machining performance, high production efficiency | – | SUM12 | – | C1109 | – | Y12 |

| – | SUM22 | 10S20 | B1113 | 220M07 | Y15 | ||

| – | SUM32 | 22S20 | C1120 | – | Y20 | ||

| – | SUM42 | 35S20 | C1130 | – | Y30 | ||

| – | – | 40S20 | C1144 | 225M36 | Y40Mn | ||

| free-machining steel | Good machining performance, high production efficiency | – | SUM12 | – | C1109 | – | Y12 |

| – | SUM22 | 10S20 | B1113 | 220M07 | Y15 | ||

| – | SUM32 | 22S20 | C1120 | – | Y20 | ||

| – | SUM42 | 35S20 | C1130 | – | Y30 | ||

| – | – | 40S20 | C1144 | 225M36 | Y40Mn | ||

| stainless steel | Good corrosion resistance, high hardness | – | SUS303 | X12CrNiS188 | 303 | 303S21 | Y1Cr18Ni9 |

| – | SUS304 | X5CrNi189 | 304 | 304S15 | 0Cr19Ni9 | ||

| – | SUS304L | X2CrNi189 | 304L | 304S12 | 00Cr19Ni11 | ||

| – | SUS316 | X5CrNiMo1810 | 316 | 316S16 | 0Cr17Ni12Mo2 | ||

| carbon tool steel | Low cutting speed, small feed | – | SK3 | – | W1-1.0C | D1 | T10 |

| – | SK2 | C125W | W1-1.2C | D1 | T12 | ||

| – | SK1 | C135W | – | – | T13 | ||

| Alloy tool steel | Used for variety of tools and dies. | – | SKD1 | X210Cr12 | D3 | BD3 | Cr12 |

| – | SKD11 | X165CrMoV46 | D2 | BD2 | Cr12MoV |

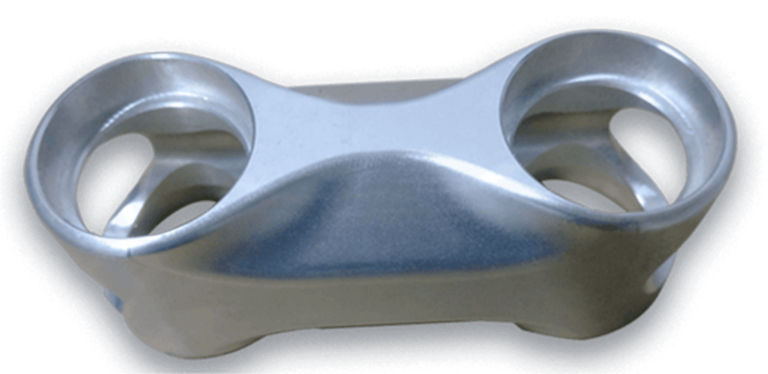

Non-ferrous metal materials are the basic materials for the development of the national economy.

Application of non-ferrous metal

The non-ferrous metal materials CNC machining are widely applied in many industries. Such as aviation, aerospace, automobile, machinery, electric power, communications, construction, and home appliances.

The most common ones for machining are aluminum, brass, copper, titanium, and alloy.

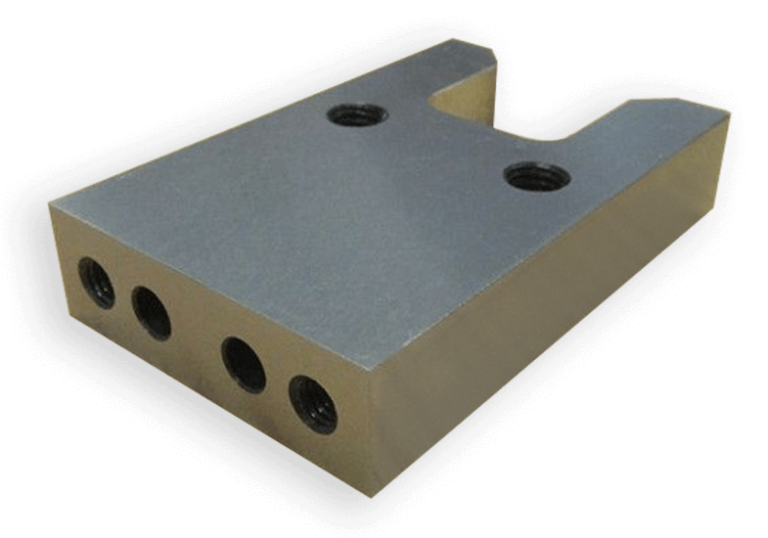

Advantages of aluminum for machining

Aluminum for machining has lots of advantages. Such as lightweight, corrosion-resistant, and easy machined cutting.

With anodizing, the parts can get the colors you like.

Application of aluminum

Aluminum machining parts are widely used. For example, electric products, aircraft, cars, trains, and ships. And also the space rockets, space shuttles, artificial satellites., etc.

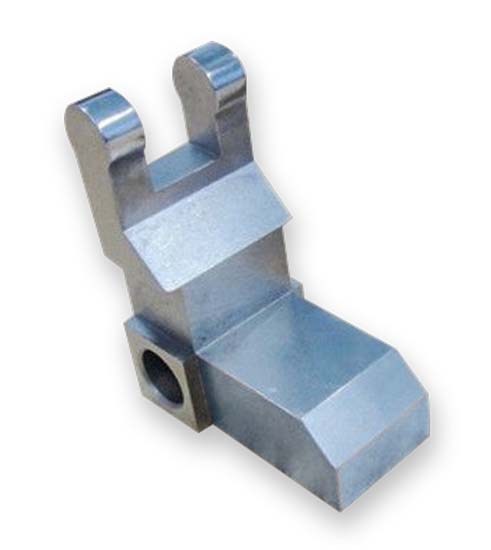

Check the A7075 aluminum drone part CNC machined by FIWOK.

Aluminum for machining

| ISO | JIS | DIN | ASTM | BS | GB |

|---|---|---|---|---|---|

| Al99.8 | A1080 | Al99.8 | 1080 | 1A | LG1 |

| AlCu4SiMg | A2014 | AlCuSiMg | 2014 | – | LD10 |

| AlCu4Mg1 | A2024 | AlCuMg2 | 2024 | GB-24S | LY12 |

| AlMg2.5 | A5052 | AlMg2.5 | 5052 | N4 | LF2 |

| AlMg5 | A5056 | AlMg5 | 5056 | N6 | LF5-1 |

| AlMg1SiCu | A6061 | AlMg1SiCu | 6061 | H20 | LD30 |

| AlMg0.7Si | A6063 | AlMgSi0.5 | 6063 | H19 | LD31 |

| AlZn5.5MgCu | A7075 | AlZnMgCu1.5 | 7075 | L95 | LC9 |

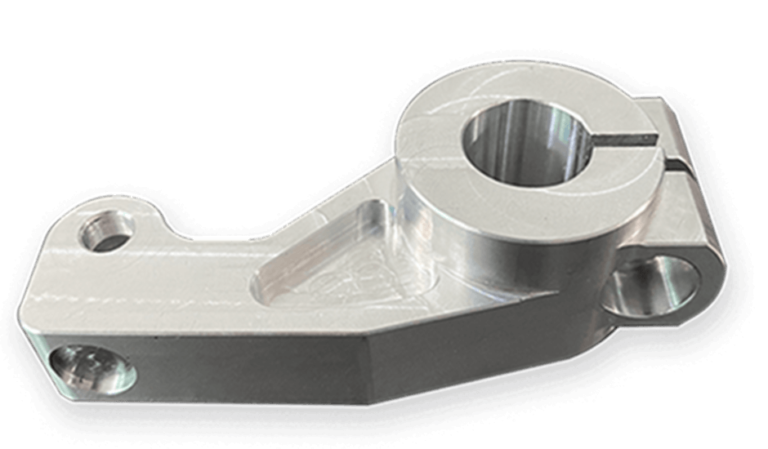

Brass & Bronze & Copper for CNC machining are different in physical and chemical properties. And some grades of materials have difficulty in machining.

Selecting the most appropriate grade to meet your need is important.

Brass & Bronze & Copper for machining

| Name | ISO | JIS | DIN | ASTM | BS | GB | NF |

|---|---|---|---|---|---|---|---|

| Copper | Cu-FRHC | C11000 | E-Cu58 | C11000 | C101/C102/C104 | T2 | Cu-a1/Cu-a2 |

| Brass | CuZn40 | C2800 | – | C28000 | CZ109 | H62 | CuZn40 |

| CuZn35 | C2700 | CuZn36 | C27000 | CZ107 | H65 | CuZn33 | |

| – | – | CuZn33 | C26200 | – | H68 | – | |

| CuZn30 | C2600 | CuZn30 | C26000 | CZ106 | H70 | CuZn30 | |

| CuZn39Pb1 | C3771 | CuZn40Pb2 | C37710 | CZ122 | HPb59-1 | – | |

| – | C3710 | CuZn39Pb0.5 | C37100 | CZ123 | HPb61-1 | CuZn40Pb | |

| – | C3560 | CuZn6Pb3 | C34500 | CZ124 | HPb63-3 | – | |

| – | – | CuZn40Mn | – | – | HMn58-2 | – | |

| CuZn37Mn3AI2Si | – | – | C67400 | – | HMn57-3-1 | – | |

| Bronze | CuSn4Zn2 | – | – | – | – | QSn4-3 | – |

| CuSn6 | C5191 | CuSn6 | C51900 | PB103 | QSn6.5-0.1 | CuSn6P | |

| CuSn6 | C5191 | CuSn6 | C51900 | PB103 | QSn6.5-0.4 | CuSn6P | |

| CuSn8 | C5210 | CuSn8 | C52100 | – | QSn7-0.2 | CuSn8P | |

| CuAI10F3 | – | – | C62300 | – | QAI9-4 | – | |

| CuAI7 | – | CuAI8 | C61000 | CA102 | QAI7 | CuAI8 | |

| – | – | CuAI10Fe3Mn2 | C63200 | – | QAI10-3-1.5 | – | |

| CuBe2 | 1720 | CuBe2 | C17200 | – | QBe2 | CuBe1.9 | |

| – | – | – | C65800 | – | QSi1-3 | – | |

| CuSi3Mn1 | – | – | C65500 | CS101 | QSi3-1 | – |

Plastic VS metal

- Easy to form, high design freedom

- Easy to color

- Easy to modify to obtain the performance you want.

- Can be stronger than metal but lighter

- Good electrical insulation

- Good water resistance

- Good chemical resistance

- Consumes less energy than metal in production

Note: Below material properties are for reference only, most of the defect properties can be changed by filling or mixing. If you have special requirements, pls let us know.

Plastic materials for CNC machining

| Name | Operating Temperature | Density (g/cm 2) | Hardness (Rockwell) | Electrical Insulating | Water Absorption(%) | Abrasion Resistant | Corrosion Resistance | Dimensional stability | Chemical Stability |

|---|---|---|---|---|---|---|---|---|---|

| PE(HDPE) | -70℃~+100℃ | 0.95~0.97 | D44-D55 | Good | 0.01 | Good | Good | Good | Good |

| PP | -30℃~ +140℃ | 0.90-0.91 | R65-R105 | Good | 0.01 | Bad | Good | Good | Good |

| PVC | -15℃~+80℃ | 1.16-1.47 | A50-A95 | – | 0.1~0.4 | – | Good | Good | medium |

| PS | -30℃~+90℃ | 1.0-1.1 | M50-M100 | Good | 0.1~0.3 | Bad | Good | Good | medium |

| PC | -40℃~+120℃ | 1.13-1.29 | R120-R125 | Good | 0.3 | Good | Good | Good | Bad |

| PA | -30℃~+80℃ | 1.1-1.2 | R75-R120 | Good | 3 | Good | Good | Bad | Bad |

| POM(Acetal) | -40℃~+120℃ | 1.4 | R118~R122 | Good | 0.3~0.4 | Good | Bad | Good | Bad |

| PPO | -127℃~+120℃ | 1.04-1.11 | R115-R120 | Good | 0.14 | Good | medium | Good | Bad |

| PEEK | -40℃~+250℃ | 1.32-1.35 | D88 | Good | 0.2 | Good | Good | Good | Very Good |

| PPS | up to 200℃~240℃ | 1.3-2.0 | R116-R123 | Good | 0.1 | Good | Good | Good | Good |

| ABS | -30℃~+80℃ | 1.0-1.1 | R95-R125 | Good | 0.5 | Good | Good | Good | medium |

| PTFE(Teflon) | -180℃~+250℃ | 1.8-2.4 | D55-D75 | Good | <0.01 | Bad | Good | Good | Good |

| PMMA (Acrylic) | -40℃~+90℃ | 1.05-1.22 | M65-M100 | Good | 0.3 | Bad | medium | Good | Bad |