CNC Milling Services

- 3-axis &4-axis &5 axis CNC milling services

- Prototypes & Small batch & Mass run

- Over 10 years experience

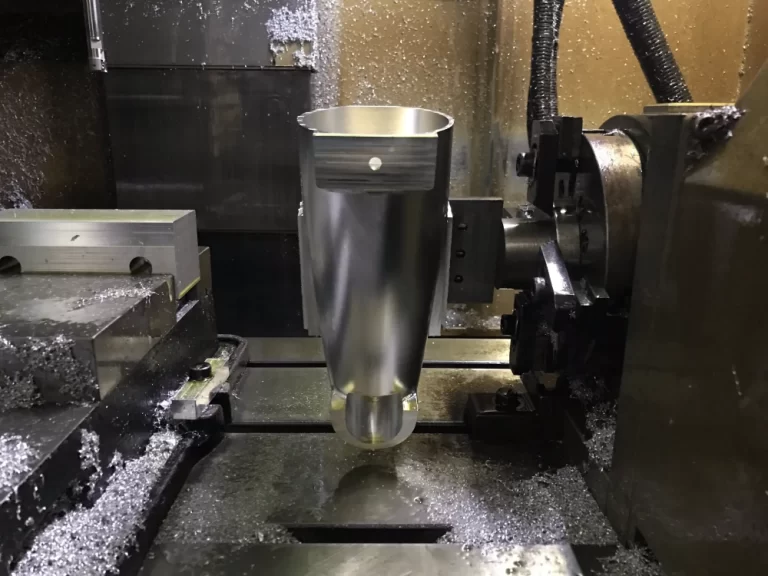

CNC Milling Solutions: From Simple to Complex Geometries

What we offer?

Get Start

Upload your CAD file → 2. Receive quote in 6hrs → 3. We machine & ship.

Even for Small Batch Focus, Big Results

No MOQ

1-1000pcs accepted

Fast Turnaround

Flexible production schedule to meet your need.

Cost Control

Mart machining solution to cut cost.

Materials for precision CNC milling machining Services

Fiwok machine high-performance parts from 50+ metals and plastics. Specializing in aerospace-grade aluminum, stainless steel, titanium, and engineering plastics (PEEK, Delrin).

We tailor solutions for:

Complex Geometries: ±0.01mm tolerances on 5-axis mills.

Surface Excellence: Ra 0.4μm finishes for medical/optical applications.

Cost Efficiency: Free DFM feedback to optimize material usage.

Fiwok’s team combines 10+ years of precision machining expertise with cutting-edge problem-solving. We specialized in:

At Fiwok, every part undergoes 100% in-process inspections.

Damage-Free Global Shipping & Custom Packaging Solutions

Design guidelines

Before or after a product is designed, it is very important to check the components’ machinability and reduce the cost. Click here to view the tips for you.